Reel-Reel RFID Encoder Tag Requirements

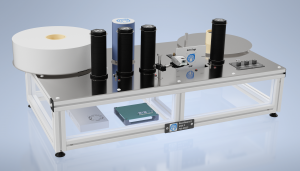

The Reel-Reel RFID Encoder is designed to encode wet and dry inlays, stickers and labels mounted on a continuous web on a roll with a 3″ cardboard core; similar to roll based printer. The Reel-Reel can not encode all products types, and some products work better than others. The general specifications for what products will and will not work are below.

If you are unsure if your tags are compatible, contact us with your tag specifications. The tags can shipped to GoToTags be run on GoToTags internal units for analysis and validation.

Contents

Related

Tag Requirements

The following are the required and maximum requirements for tags to be used in the the Reel-Reel. Tags not complying to these requirements likely will not work properly.

| Product Types | Inlays, Stickers, Labels |

| Tag Technologies | Barcode, NFC, UHF RFID |

| Chip Type | Desktop App Supported Chip Types |

| Maximum Outer Diameter | 350 mm (d) |

| Web Width | 10 – 160 mm |

| Inner Core | – 3″ (76.2 mm) cardboard core – Includes washers for tension adjustment |

| Bending Radius | 30 mm (r) |

| Tag Thickness | – 0.10 – 0.35 mm – Tags thicker than an inlay/sticker/label not reccommended due to peeling over rollers |

| Leading and Trailing Liner | 1 m (required); enough to attach web to rewinder with the first tag positioned before the fist tag sensor |

| Web | 1-up tags |

| Tag Detection | – Infrared sensor for gap or registration mark – Within 0 – 15 mm from bottom edge of web – Minimum of 5 mm gap |

| Joins | Joins may cause issues with tag detection |

| Cut | – Kiss cut: ok – Die cut: not supported – Continuous: ok, registration mark required – Perforated: not recommended due to potential for tearing – Solid (dry inlay): ok |